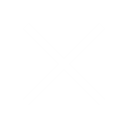

Production Planning and Control

Optimize your production workflow, advanced planning tools, tracking KPIs to enhance efficiency. Seamlessly allocate resources and adapt to changing demand for maximum profitability.

- Gives you hand in managing workflow for you.

- Tracks key performance indicators (KPIs) to assess production efficiency

- Distributes labor, machinery, and resources successfully to exploit production efficiency and minimize prices.

- Facilitates modifications to manufacture strategies in response to unexpected fluctuations in demand

Quality Management

Ensure top-notch quality real-time data analysis and robust monitoring of production standards. Our system tracks non-conformance and generates comprehensive reports to maintain industry compliance.

- Analyzes data in real time to identify quality trends and potential issues.

- Tracks and manages instances of non-conformance to standards.

- Establishes consistent procedures for quality checks at various stages of the production.

- Generates reports and documentation to demonstrate agreement with industry guidelines.

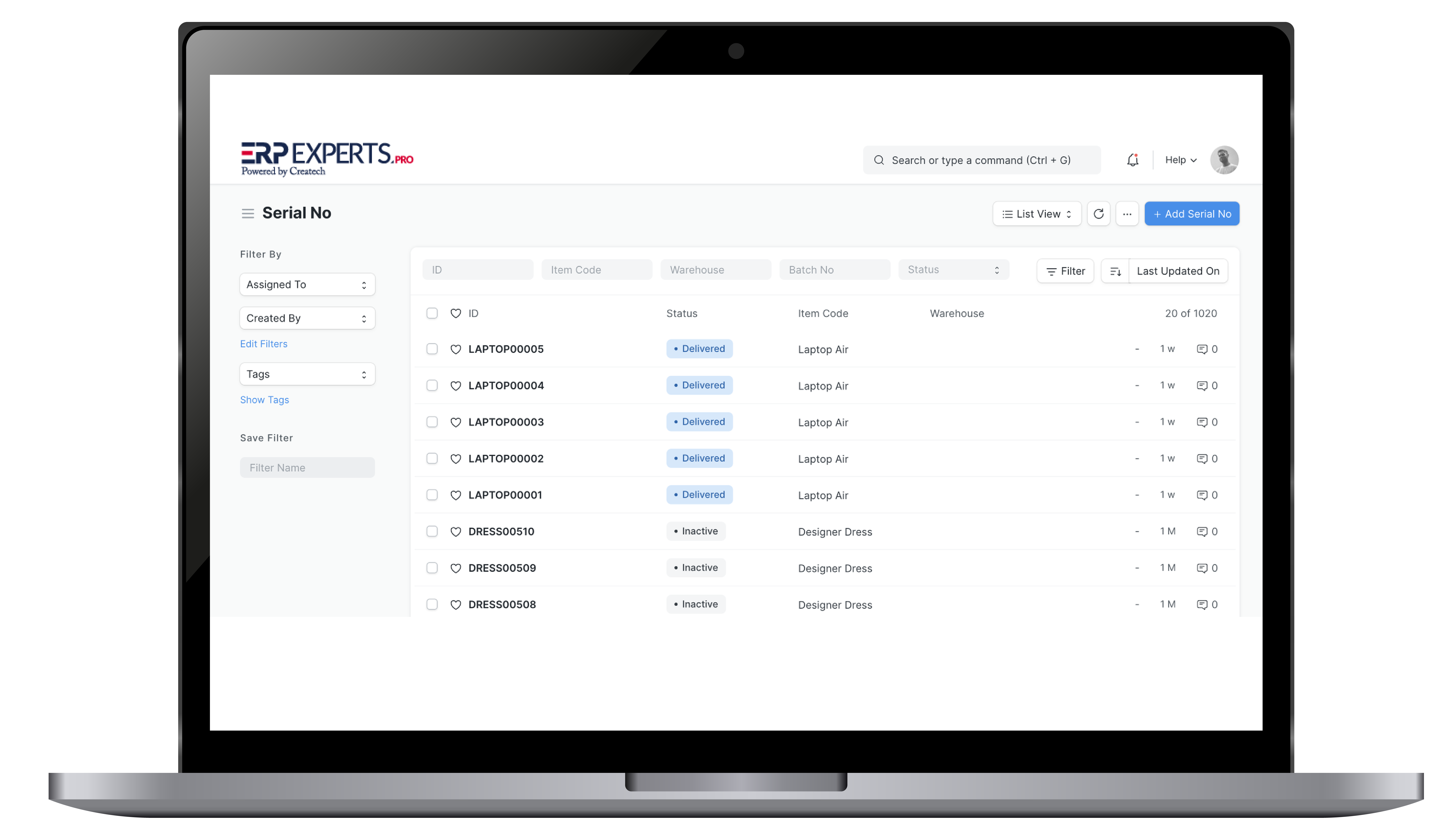

Bill of material (BOM)

Simplify your manufacturing process hierarchical Bill of Materials (BOM) management. Access critical product details and enhance accuracy for efficient production.

- Bill of Materials (BOM) is essential for cloud manufacturing software, providing a foundation for robustness and accuracy.

- Features a hierarchical BOM structure, placing the finished product at the top of the hierarchy.

- BOM includes critical details such as product codes, part descriptions, quantities, and costs.

- Additional specifications can also be included in the BOM to enhance clarity and precision in manufacturing processes.

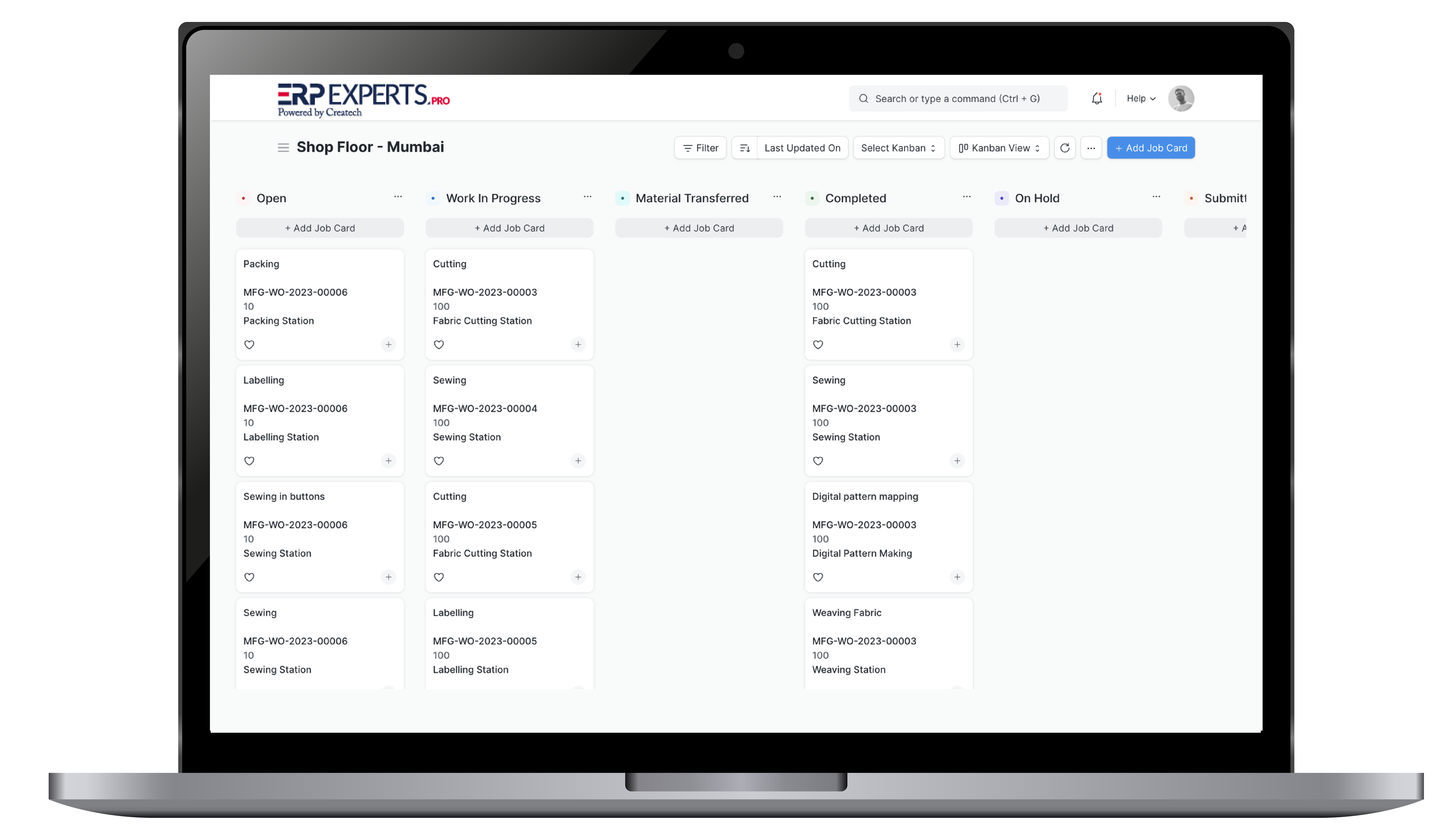

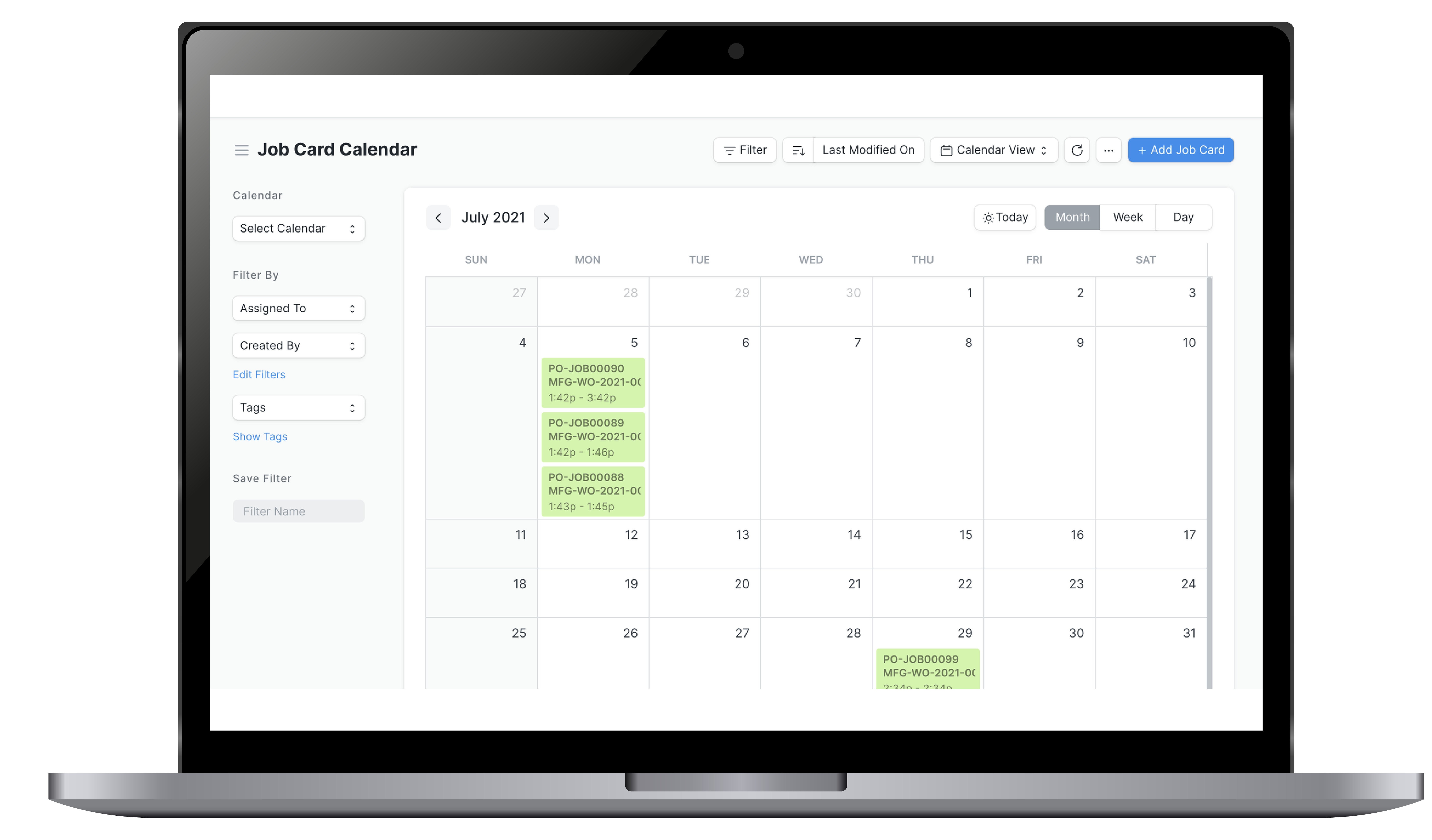

Shop Floor Management

Streamline your shop floor operations, intuitive management system. Monitor workstations, employee assignments, and job statuses all in one place for maximum productivity.

- Software provides the location of every workstation and employee assignments.

- Current status and pending steps for each work order can be monitored on one screen.

- ExpertERP job cards automatically capture daily activities on the shop floor.

- Users can view the real-time status of job work being done to manufacture products.

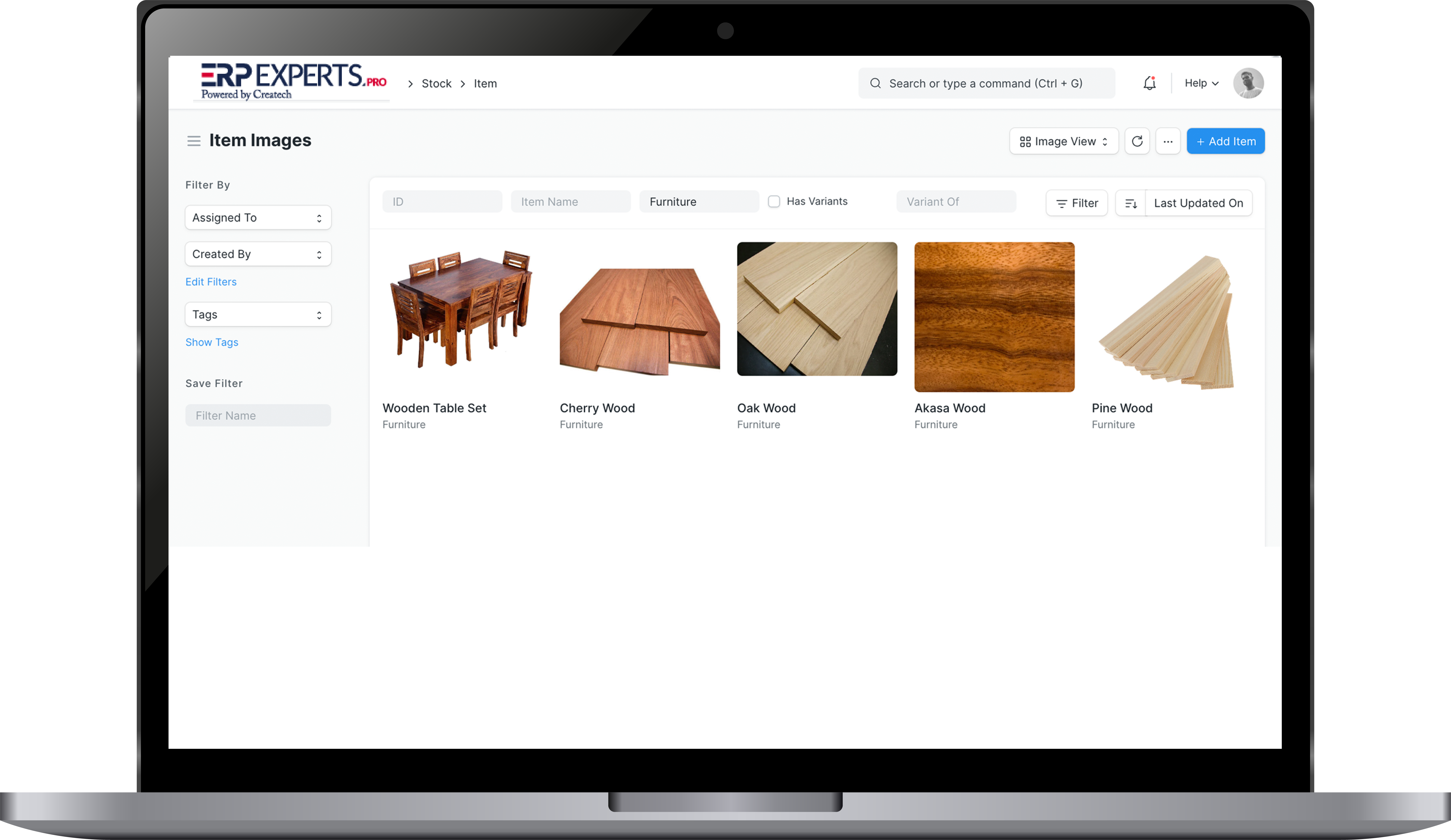

Manage Inventory

Take control of your inventory real-time monitoring and streamlined management processes. Stay ahead of stock levels to prevent disruptions and optimize storage space.

- Monitors your inventory in real time lets you know the item variants and batched inventory.

- Gives you hand in streamlines processes such as receiving, picking, packing, and shipping.

- Keeps your storage space free by minimize overstocking.

- Alerts you on low inventory to avoid interruptions in production.

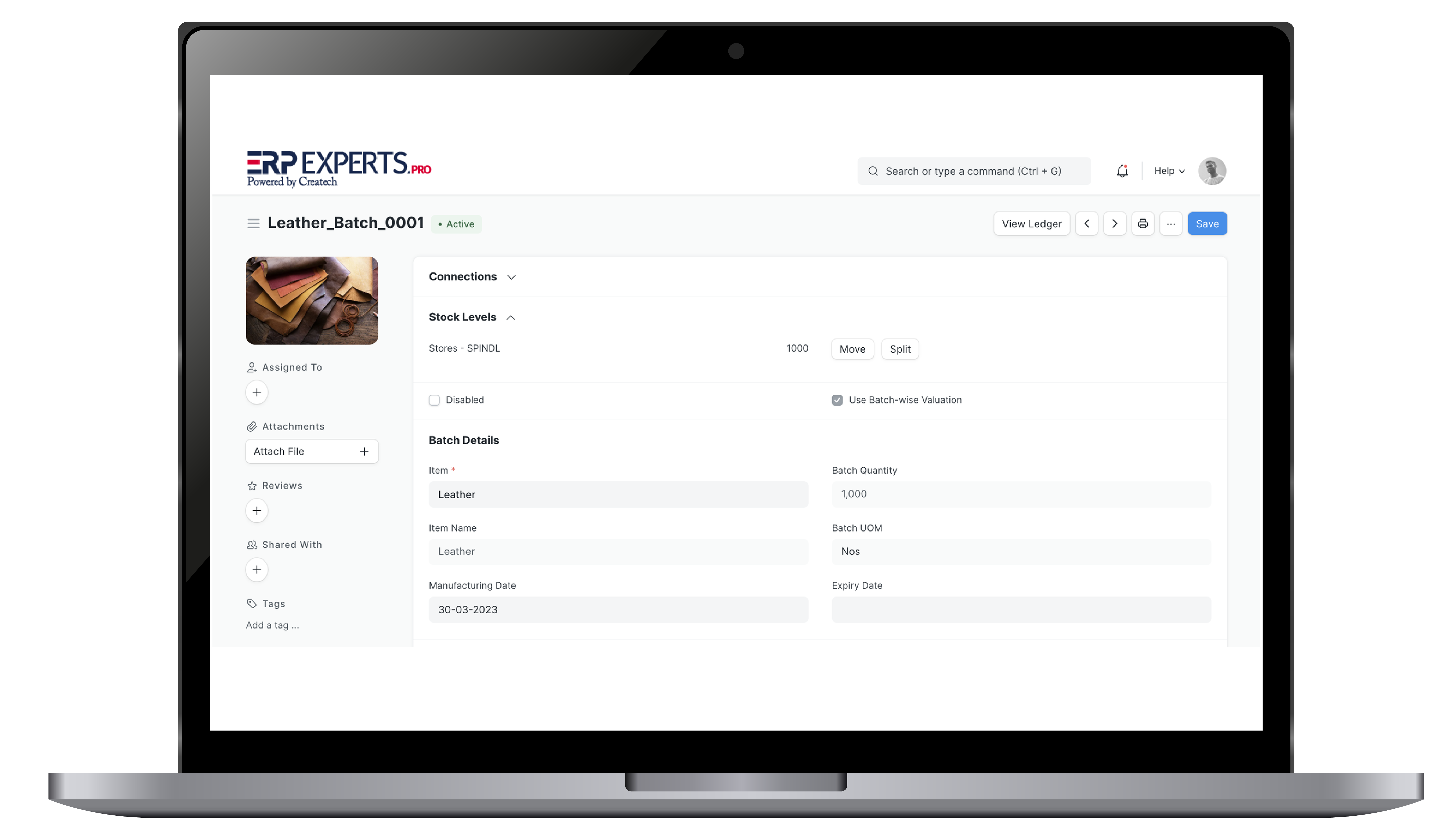

Batched inventory

Effortlessly manage batches integrated inventory tracking system. Stay compliant and make data-driven decisions to reduce waste and improve stock turnover.

- Real-time tracking of product availability, manufacturing, and expiration dates for each batch.

- Easy barcode scanning via device camera for quick stock search and updates.

- Streamlined compliance with traceable batch information for quality control.

- Data-driven inventory decisions to reduce waste and optimize stock turnover.

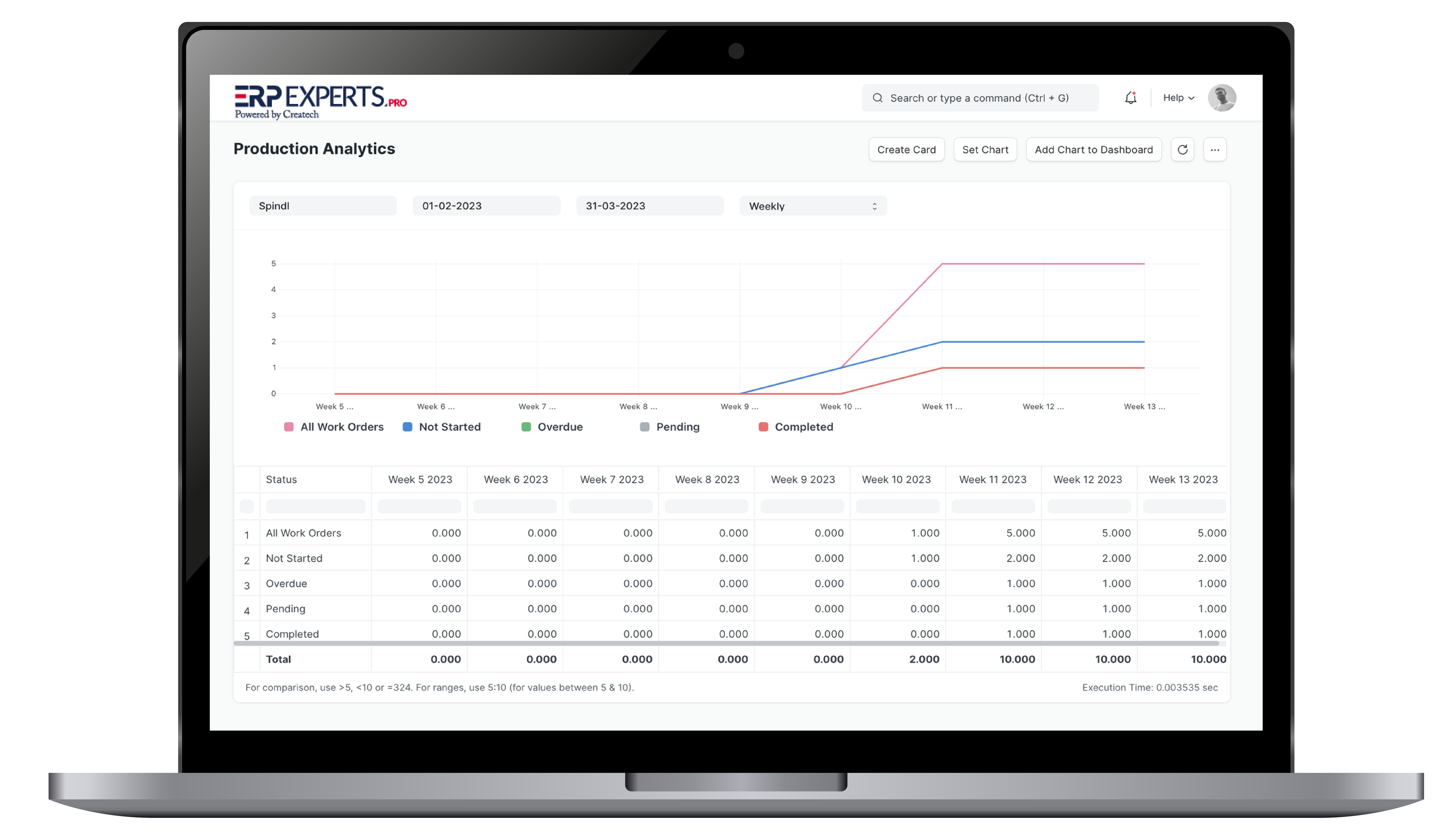

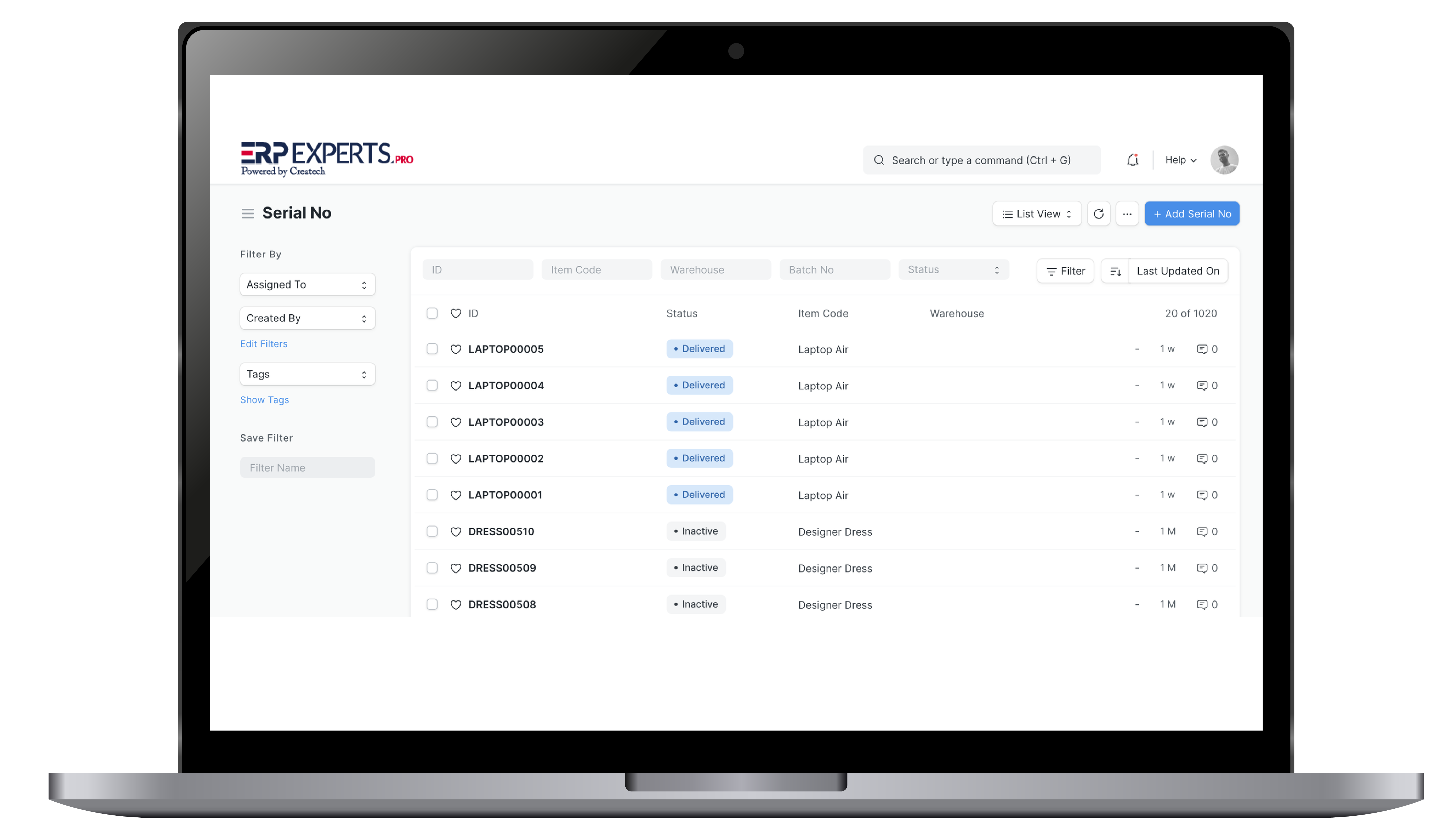

Serialized Inventory

ExpertERP allows for precise tracking of your inventory using unique serial numbers. Simplify searches and manage stock efficiently with barcode scanning capabilities.

- Use serial numbers to uniquely identify units.

- Set up a naming series, and will automatically create serial numbers for new stock.

- Scan item barcodes via your device camera for easy searching.

- Search through all your stock efficiently with scanned barcodes.

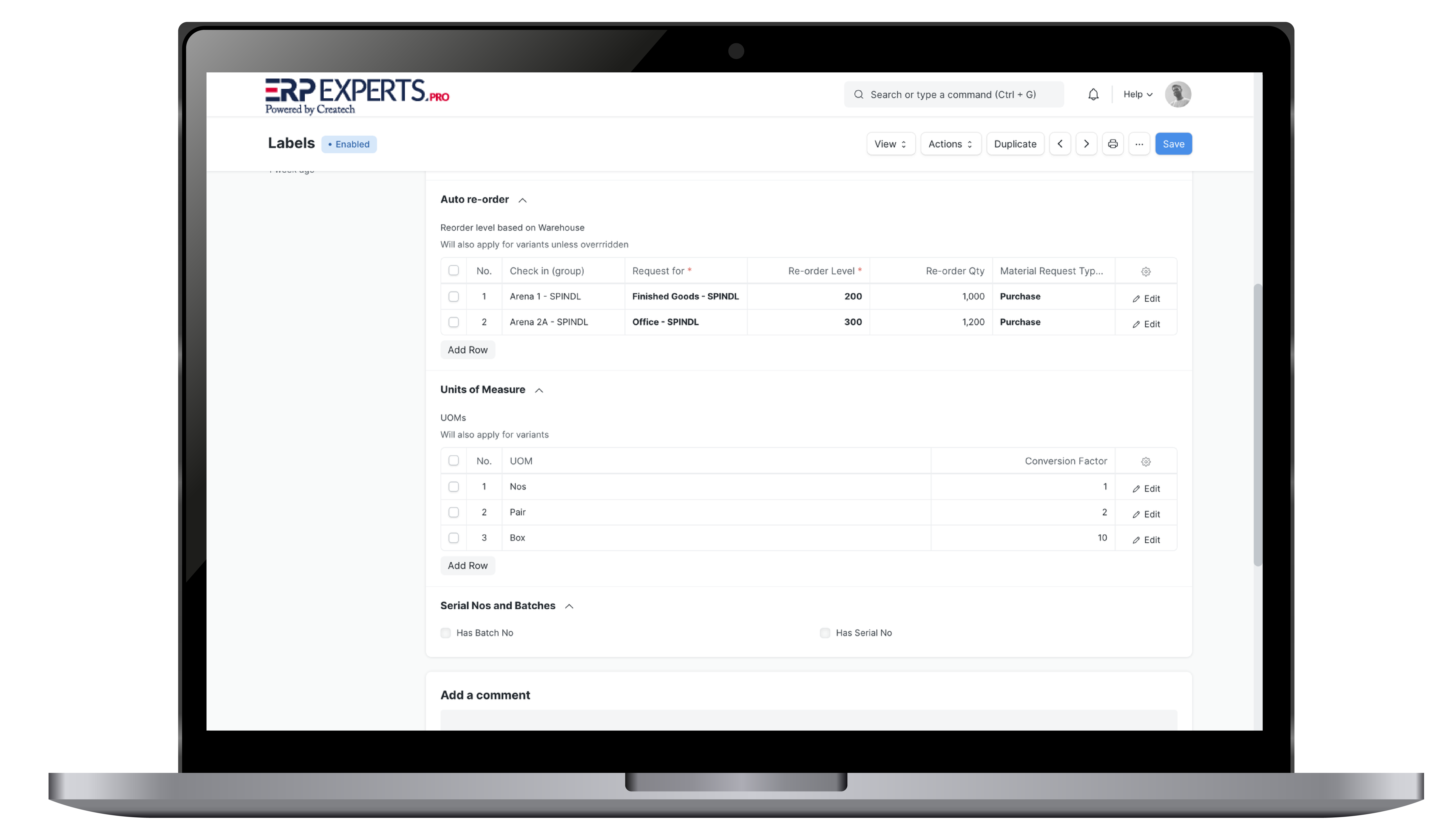

Stock Replenishment

Ensure timely stock replenishment with us automated tracking system. Stay proactive in inventory management to avoid stockouts and maintain optimal levels.

- Track an item's reorder level to prevent stockouts effectively.

- Automatically create a material request when stock levels fall below the reorder level.

- Replenish inventory at the right time to maintain optimal stock levels.

- Reduce the chances of stock exhaustion with proactive inventory management.

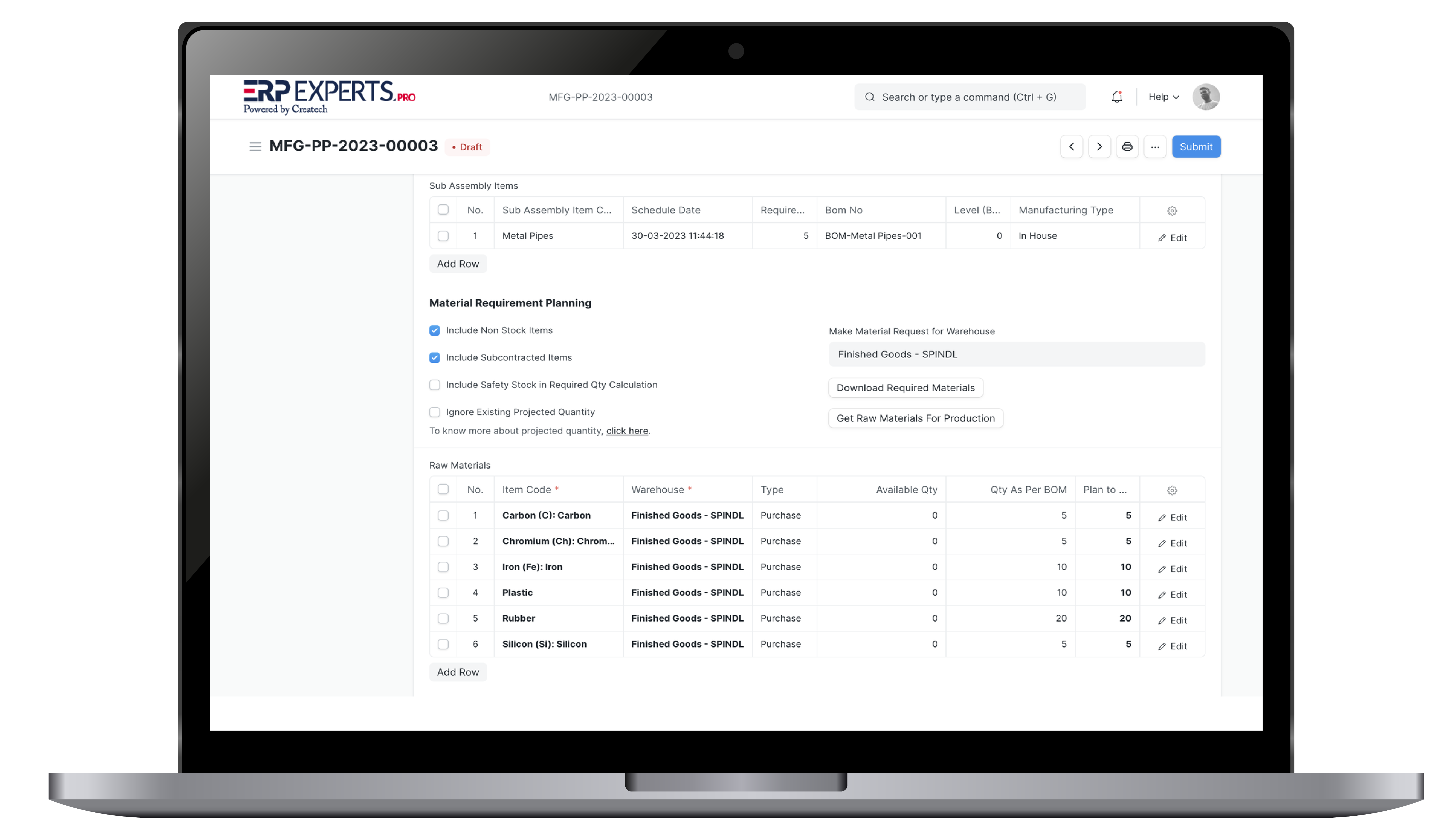

Material Resource Planning

Gain comprehensive insights into your Material Requirements Planning (MRP). Effectively track material usage to minimize waste and curb expenses.

- Provide a comprehensive view of your Material Requirements Planning (MRP) for work orders and material requests.

- Track material consumption for serialized or batched inventory effectively.

- Curb expenses by monitoring inventory usage closely.

- Achieve zero wasted resources through precise inventory management.

Capacity Planning

Optimize your production capacity with us strategic planning tools. Identify bottlenecks and streamline resource allocation for improved efficiency on the shop floor.

- Optimize workstation performance based on available resources.

- Identify and eliminate bottlenecks at the shop-floor level.

- Create capacity plans for improved production efficiency.

- Manage planning schedules for specific periods (30, 45 days, etc.).

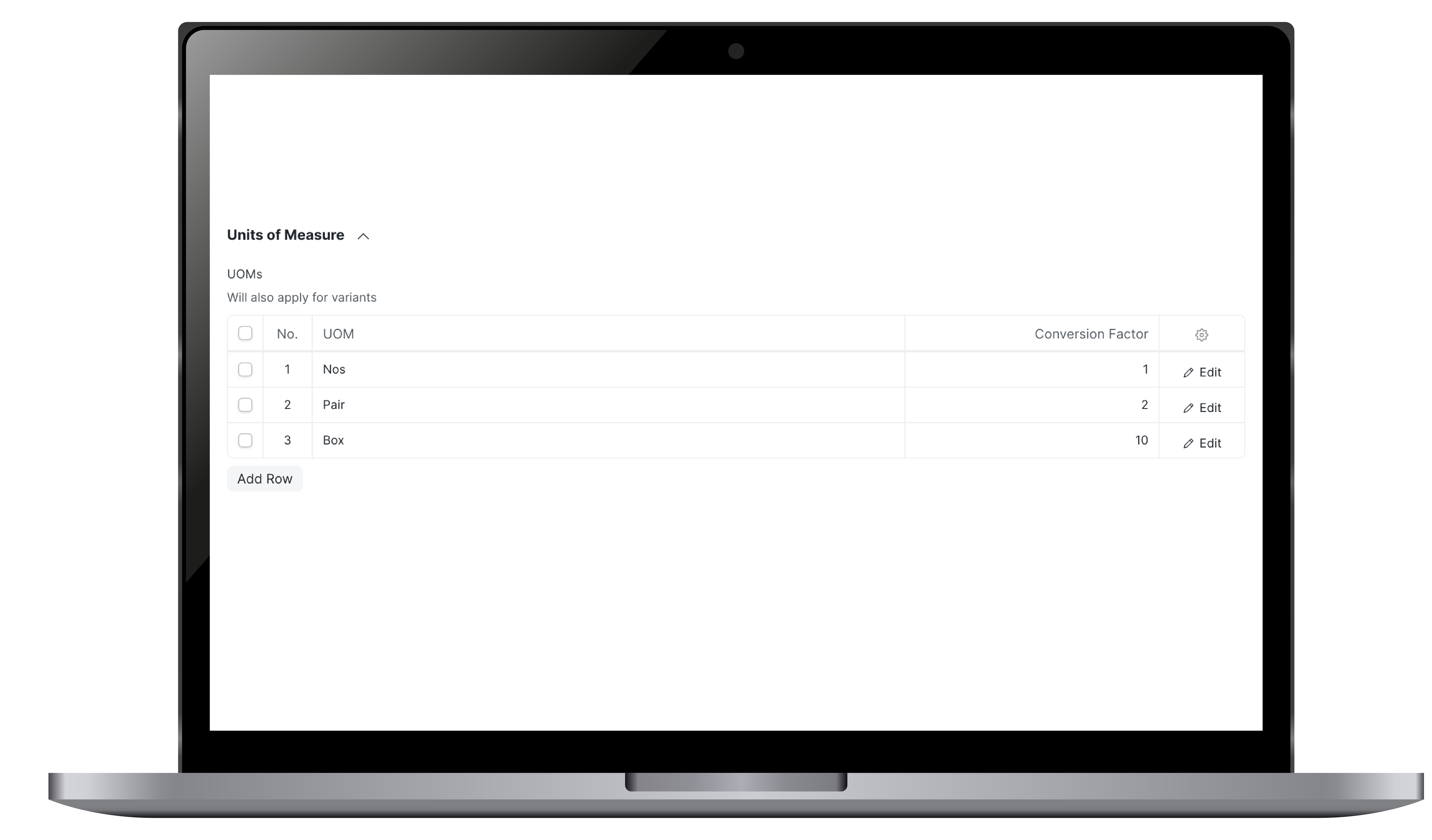

Multiple Units of Measure

Seamlessly manage various inventory measurements conversion tools. Automate processes for smooth sales and stock transactions across different units of measure.

- Manage different units of measure for various materials.

- Set up custom conversion factors in the Item master.

- Facilitate smooth sales, purchase, and stock transactions.

- Automate conversions for accurate and efficient operations.

Quick Stock Balance

Conduct efficient stock audits, quick stock balance reporting feature. Ensure real-time accuracy and make informed decisions with easy barcode scanning.

- Perform stock audits by comparing system data with physical inventory.

- Scan barcodes using any device, no additional equipment needed.

- Start stock counting immediately after scanning.

- Ensure real-time stock accuracy for informed decision-making.

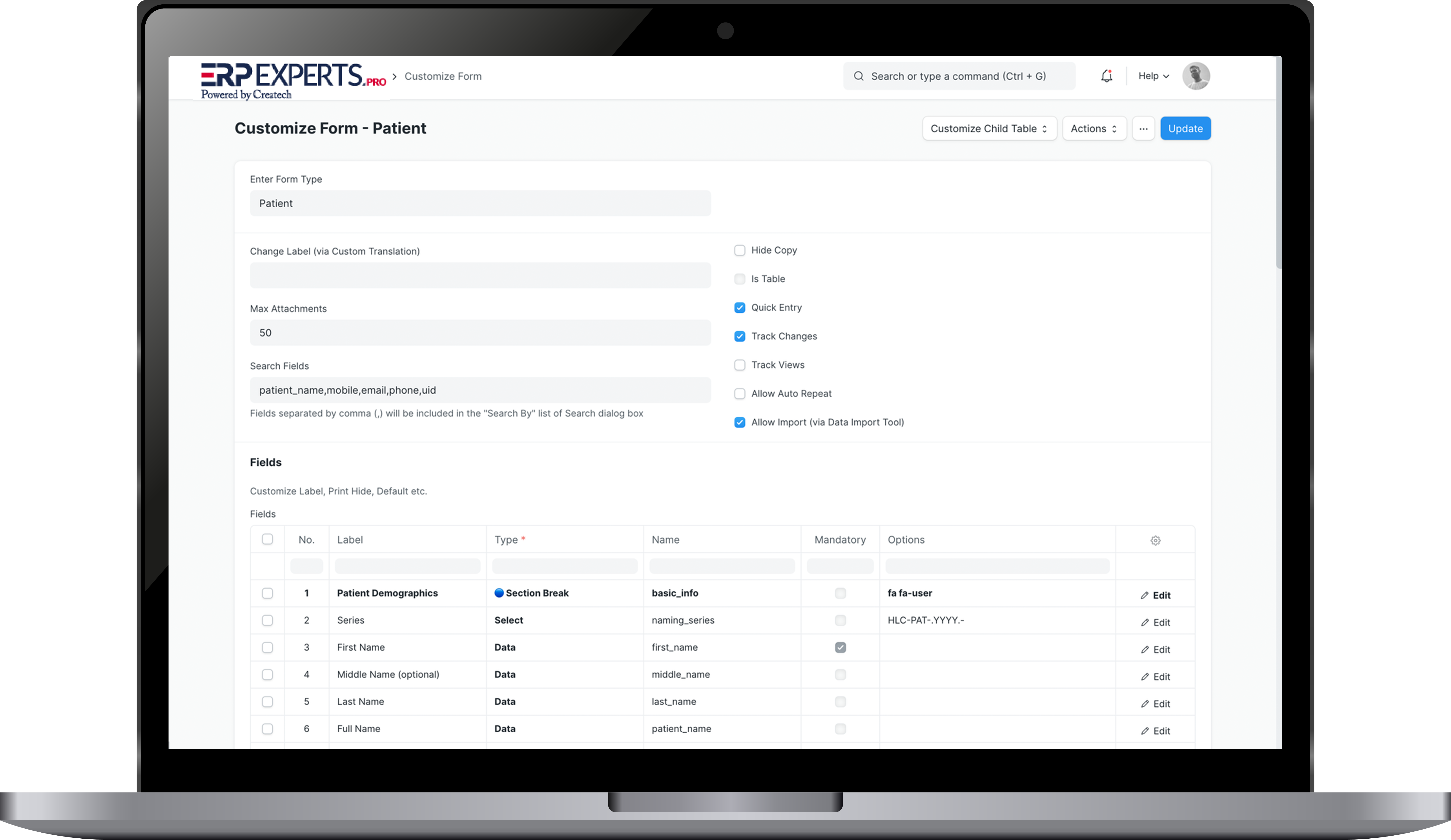

On-the-fly Customization

Tailor your experience with on-the-fly customization options for inventory management. Enhance data entry efficiency and security with personalized forms and fields.

- Create custom cloud manufacturing ERP software by mapping important data with custom fields in forms.

- Customize form behavior by auto-fetching values for improved data entry efficiency.

- Hide fields based on user roles to enhance user experience and data security.

- Design custom print formats without writing a single line of code for tailored document outputs.

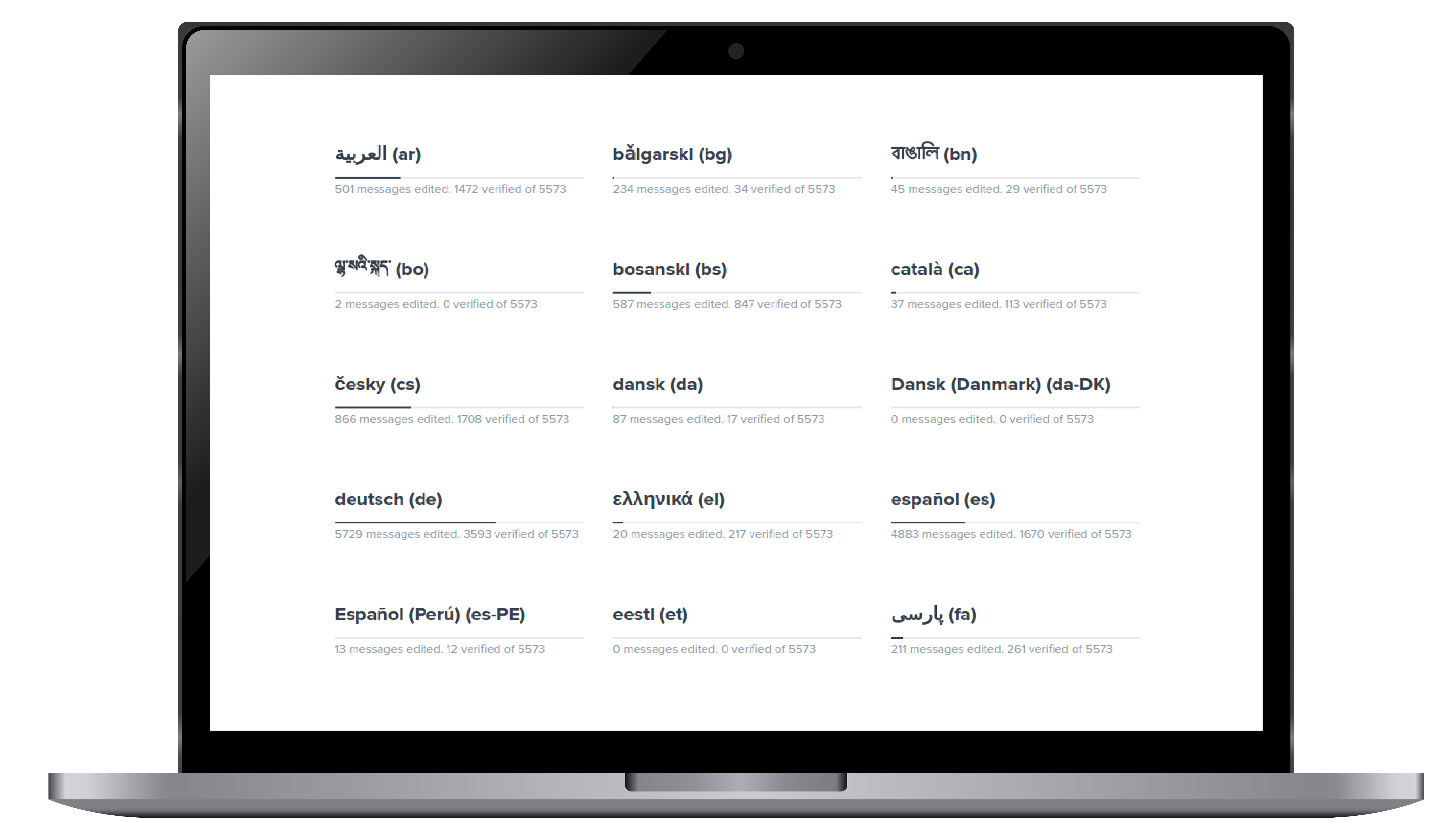

Multilingual manufacturing management software

Work in the software using the language you’re most comfortable with, offering support for multiple languages to accommodate international teams and users

Our features

Discuss your project

Have something in your mind for your business but do not know where to start?

Tell us about your idea and we will help you start your project.